During rotation of a bearing the grease is mechanically worked and a change in consistency may result. Needle roller bearings include drawn cup.

Needle roller bearings include bearings whose rollers slightly exceed the size range of needle rollers as stipulated by ISO.

Add grease to bearings roller. Of grease into your palm. Using your opposite hand push the large end of the bearing cone assembly into the grease forcing grease between the rollers cage and cone. While pushing grease into the large end rotate the entire cone assembly until the grease is forced out evenly around the entire small end.

10 Film Thickness in Grease Lubricated Rolling Bearings 227 101 Thin Layer Flow on Bearing Surfaces 228 1011 Contact Replenishment in Bearings 228 1012 Thin Layer Flow Induced by Centrifugal Forces 231 1013 Combining the Thin Layer Flow on the All Bearing Components 233 102 Starved EHL for Rolling Bearings 234 1021 Central Film Thickness 234. When lubricating bearings add grease slowly while the shaft is rotating. When grease begins to come out of the seals the bearing will contain the correct amount of grease.

Re-lubricate with a lithium soap grease with EP additive which conforms to NLGI 2 consistency and is suitable for an operating range of -20F to 250F. Recently at a Louisiana mill grease-lubricated spherical roller bearings in a paper machines press roll section were experiencing a high rate of failure due to roller skidding. The skidding occurred when the bearings rolling elements ceased rotating after leaving the load zone during operation and began to skid instead of rotating when.

Greases with a metallic soap thickener and a consistency grade of 1 2 or 3 soft to stiff on the NLGI scale are typically used for rolling bearings. The most commonly used greases have a consistency of grade 2. During rotation of a bearing the grease is mechanically worked and a change in consistency may result.

The problem with heavy grease is that it may cake up those little rollers and not grab the tube. Some that I know use a light grease on roller bearings like Yamaha Blue Grease and report no problems. I do use a lite coat of yamaha grease on the inside side plate and then slide the roller bearing in.

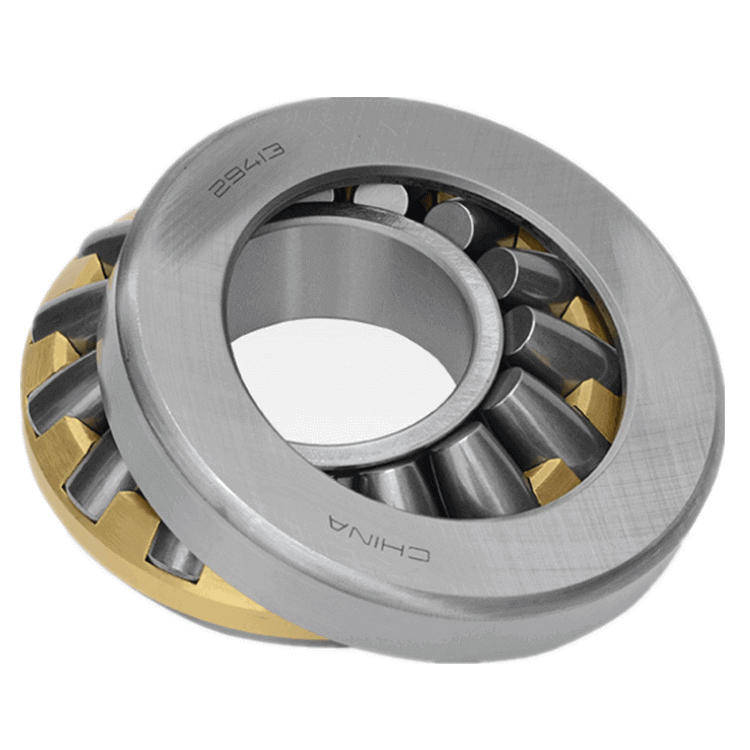

Roller bearings are a vital part of the traction system provided on axle ie. Axle box motor suspension unit as well as traction motor at both the ends. They are mainly grease lubricated cylindrical roller bearings and are used to support axle or wheel set of the locomotives and armature of traction motors.

Low the excess grease to vacate the element path when the machine is put into service. In addition to the grease introduced into the element spaces enough grease should be placed into the housing to bring the grease level up to the lip of the bottom race of the bearing. When the excess from the initial fill is pushed away.

Extremely long resistance to high temperatures excellent protection against wear and corrosion for ball and roller bearings for horizontal and vertical shafts. TEMPEraTUrE raNGE from -40C to 160C This grease is the ideal solution for long-term lubrication at high temperatures up to 150C. Accepts occasional peaks at 175C.

This grease is helpful in applications where there are chances of impurities to enter the bearing. Bearings can be divided into mainly two types separable and non separable. No matter what type of bearing it is the general practice is to fill up the spaces inside the inner race outer race and the rolling components on each side of the.

V 24 mm2s ISO VG68 for thrust roller bearings Oil bath with the oil reaching up to the middle of the rolling element in the lowest position. For grease lubricated bearings. Regular lithium soap grease with mineral base oil having a viscosity.

The goal of this 4-year project is to measure and model film thickness in grease lubricated cylindrical roller bearings. This requires a thorough understanding of Elasto-Hydrodynamic Lubrication EHL thin film lubrication properties of oils and grease lubrication mechanisms. The quickest and easiest way to grease a wheel bearing is with a bearing-packing tool.

This device works either through hand or by air pressure to force the grease up into the cavities between the rollers cage and inner and outer rings. An alternative and widely more available ways for cleaning and lubricating greasing your inline or roller hockey skate bearings if traditional products lik. Grease life for sealed spherical roller bearings with designation sufix VT143 where P 0125 C Grease life L 10 h Operating temperature C n rotational speed rmin dm bearing mean diameter mm 05 d D Table 2 Speed limits for grease life calculation for sealed spherical roller bearings Bearing series Maximum nd m value Light load.

Needle roller bearings are a type of roller bearings and are classified as either radial or thrust depending on the direction of the load they support. Needle roller bearings include bearings whose rollers slightly exceed the size range of needle rollers as stipulated by ISO. Needle roller bearings include drawn cup.

Insert grease filled bearings. Please insert it from the inner bearing first. Raise the oil seal from above and apply lubricating grease to the lip portion of the oil seal as initial lubrication.

Before pushing in the hub clean the spindle clean the old grease push the hub into position insert the outer bearing and washer and set the locknut.