You could average it out to a stroke every 8 weeks or so. IF the bearing or machine manufacturer specifies the amount of grease to be packed in the bearing as a percentage of free space and not a specific volume or weight then it is really very simple.

Using grease to keep water out isnt the answer.

How much grease do you put in a bearing. How Much Grease Should You Put In A Bearing. In order to better extend the service life of the motor bearings and ensure the normal operation of the bearings the motor bearings need to be lubricated and maintained regularly. The main effect of grease on motor bearings is lubrication protection and sealing.

This is done by pumping a known number of strokes on your grease gun and weighing the discharged grease on a scale. As an example of using this formula lets consider a sealed bearing on a 2 diameter shaft that is 78 of an inch wide. 2 x 82510 016 oz of grease.

Rule of Thumb 2. One Stroke per Inch of Shaft. The product of these two parameters along with a constant 0114 if inches are used for the other dimensions will give you the grease quantity in ounces.

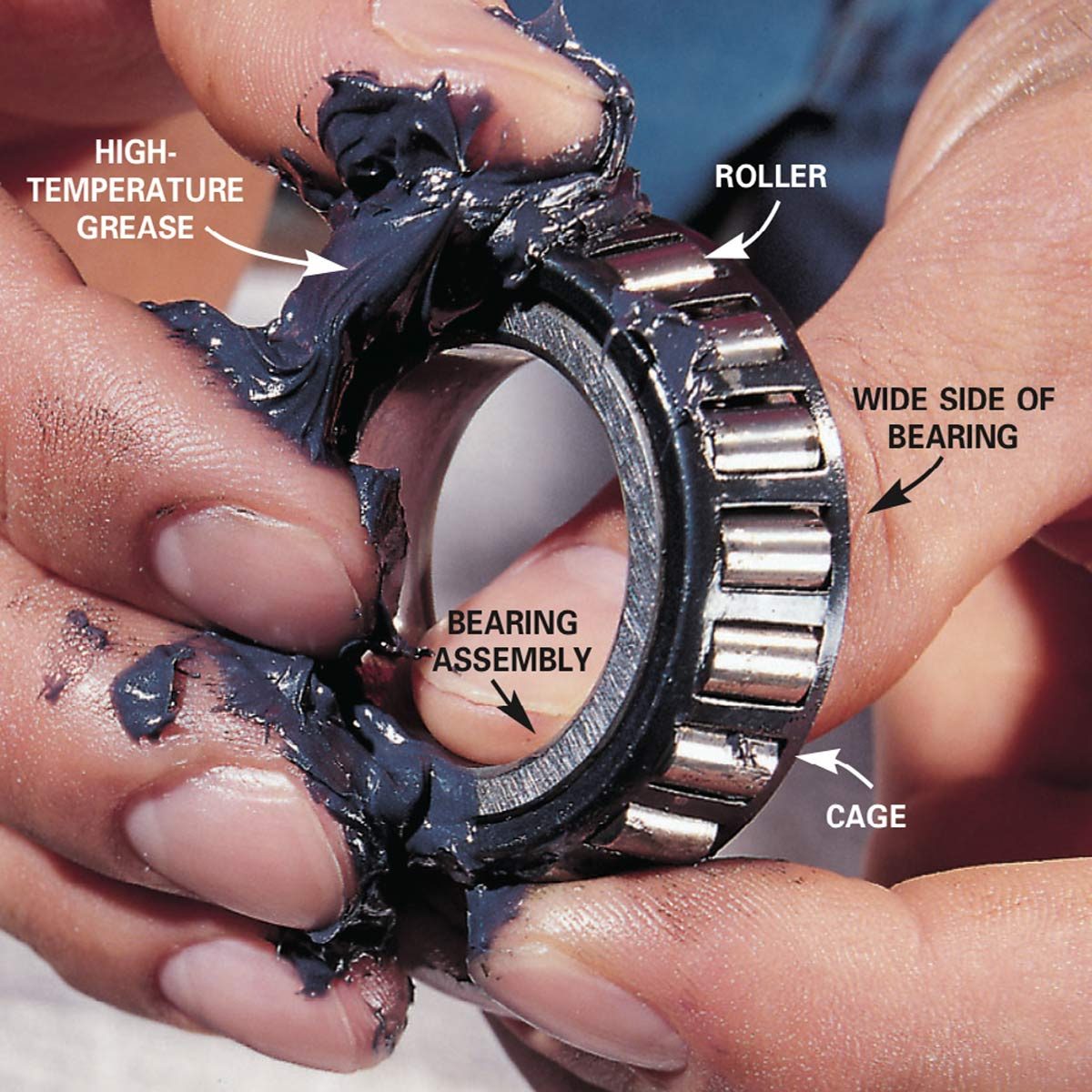

There are a few ways to calculate the relubrication frequency. Try Norias bearing grease volume and frequency calculator. The grease should work its from wide side to narrow side your fingers are in the race slowly work the bearing around until the grease has worked its way between all the bearings and inner and outer races.

Place the bearings back into hub. A small amount of grease may be put in the hub between the bearings. Using the chart and the formula the bearing only needs 8 grams of grease every 10000 hours.

If your grease gun delivers around 135 grams per stroke that means the bearing needs 6 strokes every 13 months. You could average it out to a stroke every 8 weeks or so. I currently teach my technicians to add the amount of grease as determined by the SKF formula G DB10 where G is grease in ounces D is bearing outer diameter and B is bearing width.

Or as Ive read in Lube-Tips one shot per inch of shaft diameter. Normally the manufacturer of a machinery would recommend the type or grade of grease to be applied but what is not on record normally is the quantity to be applied so we will talk more about the best bearing grease application aspect in the subsequent section. IF the bearing or machine manufacturer specifies the amount of grease to be packed in the bearing as a percentage of free space and not a specific volume or weight then it is really very simple.

On that bearing that tool maker posted a picture of I count 18 balls. How much grease to pump into a gimbal bearing for maintenance. The excess grease goes into the bellows.

5-10 pumps is sufficient. If the bearing ever gets wet all ya have to do is wet it once and it fails. A day a week a month.

Problem is once water is in the bearing there is no way to remove it. Pump all you wish but the water slurry is there. Some get lucky 95 fail after swiming gimbal bearings.

Tity of grease to fill the bearing is determined by the fol-lowing equation. This is a simple method of calculating the amount of grease needed for a standard application. Quantity of grease g Outer bearing diameter mm X bearing width mm X 0005 or Quantity oz 0114 X bearing OD in X bearing width in It is common practice to pack the bearings as well as the.

Doing this manually is suitable assuming the drive is not too large. When its rotating the motion of the rolling elements will do some of the work for you distributing grease within the bearing cavity. By distributing the grease this way before operation this will minimize the capacity for the grease to blow a seal when overfilled.

When subjecting a bearing to a hard start with grease. Electric Motor Bearing Greasing Basics. Amount of Grease to Use.

The general procedure for greasing is as follows. Lock and tag out the electric motor. Wipe grease from the pressure fitting clean dirt debris and paint around the grease relief plug.

This prevents foreign objects from entering the grease cavity. In addition the presence of too much grease means that the anti-friction bearing elements have to push through this excess grease making it harder for the bearing to do its job. That means more losses and even less efficiency.

There are more complications that can arise from using too much grease however. HOW-TO Grease A Sealed BearingEver wonder if sealed bearings can be greased. Follow along as I show you how easy it is to doDont forget to click the to.

Generally the smaller the tire the faster the wheels spin which puts stress on the bearings. In this manner how much grease do you put in a bearing. FOR STARTERS note that most sealed bearings come pre-greased from the factory with a 25-35 grease fill.

This is all the grease the bearings will ever need because the relubrication interval explained below is longer than the expected life of the bearing. Its easy to put too much grease in the hubs and will cause overheating and leakage. Your bearing pack looks good wipe a little over the rollers fill the hub about even with the races a little on the seals and birf splines good to go.

To properly grease a bearing put enough grease in your hand to cover your palm. Since you said its a taper bearing place your index finger down through the center of the bearing. Your bearing hand as opposed to your grease hand should be facing palm down.

The wide end of the bearing should also be pointing down. The idea of grease is that it gives a solid film that a bearing or shaft can roll over. If there is too much grease packed inside a bearing the bearings rolling elements will have to push through the grease rather than roll over it.

This churning through the grease causes overheating accelerated oxidation and will often cause the oil. You can manually check the Bearing Buddy to be sure it has enough grease. All you need to do is press the edge of the piston.

If you can move or rock the piston it has enough grease. I have attached a drawing of a Bearing Buddy you can check out to see what the components are. Bearing Buddy pumps grease into the center of the hub all the way back to the grease seal.

A double lip seal should be used to prevent grease from blowing out the seal when added. It would then fill the cavity inside the hub and continue to the inner bearing. Similarly how do I know if my bearing Buddy has enough grease.

You can manually check the Bearing Buddy to be sure it has enough grease. All you need to do. Too much grease causes excessive heat.

If you are driving 2 miles to the lake and back its no big deal. On a longer trip you could have issues. Using grease to keep water out isnt the answer.

Any water and all of the grease is contaminated and will cause the bearings. How much grease do you put in a trailer wheel bearing. It is equally important to retain the grease around the bearing.

For traditional greases NLGI Nos. 1 and 2 pump a ring of grease into the entire circumference of the wheel hub and coat the hub cap inner wall.